Below is a quick prototype of a dual threaded mason jar lid. I designed the CAD and 3D printed the part with future injection molding in mind.

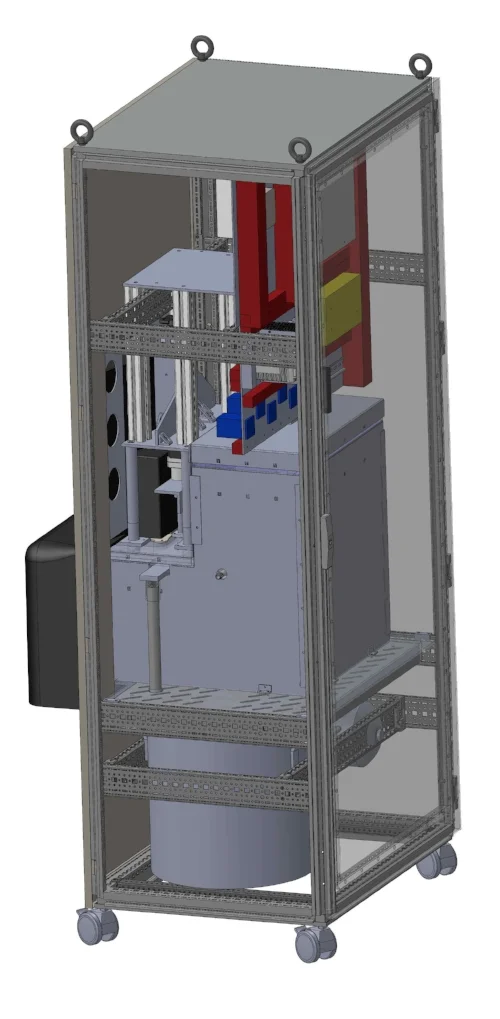

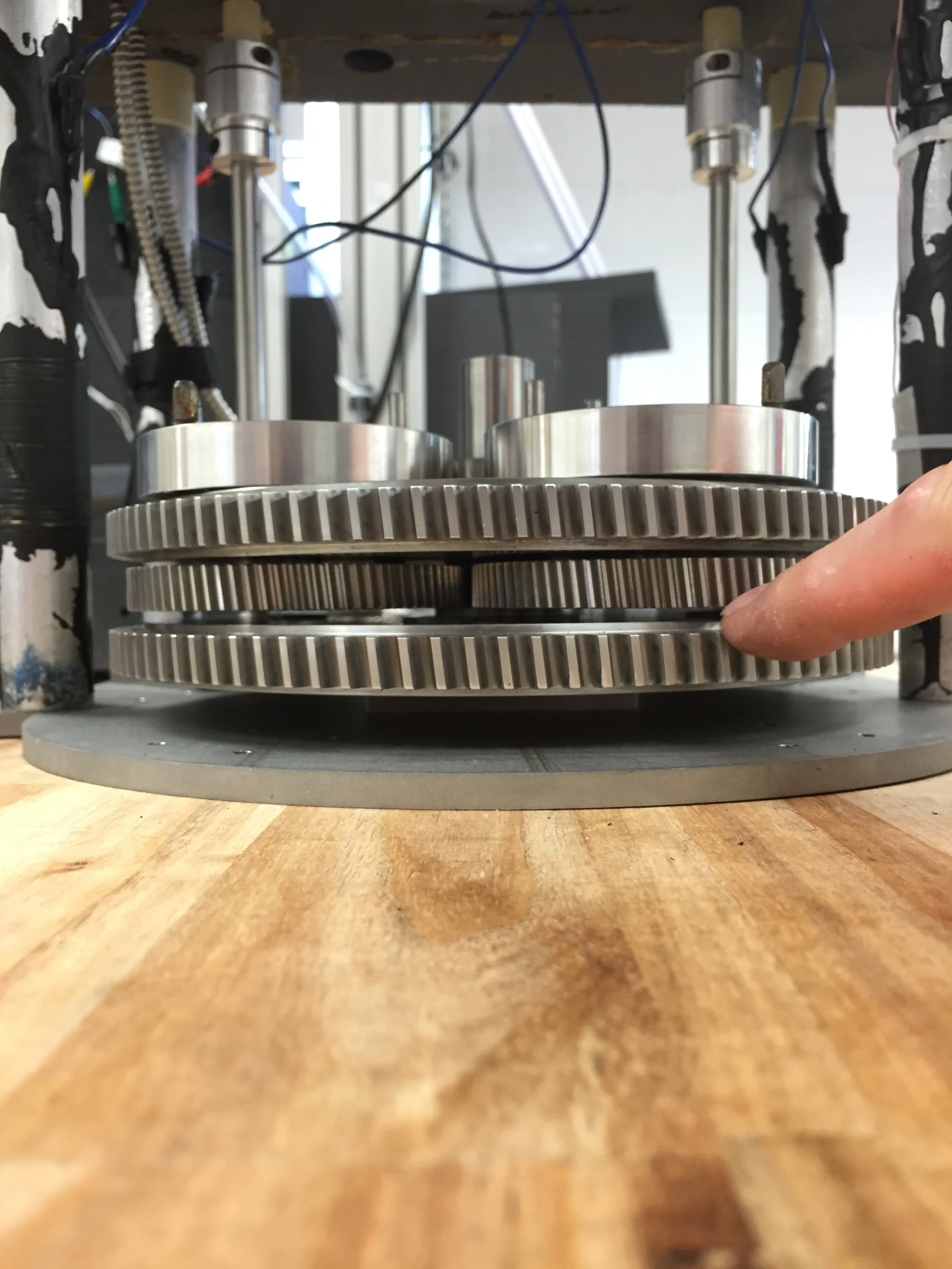

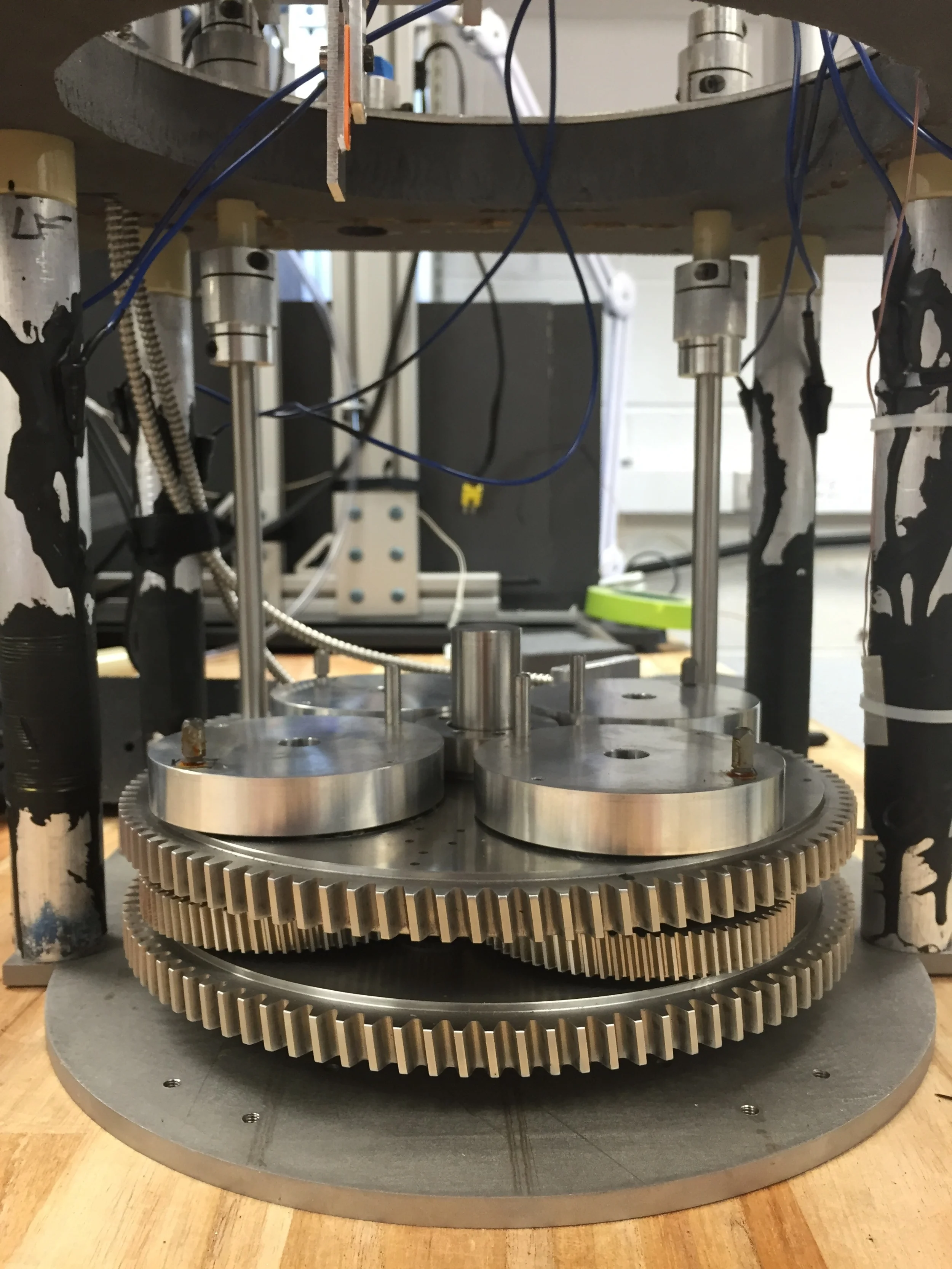

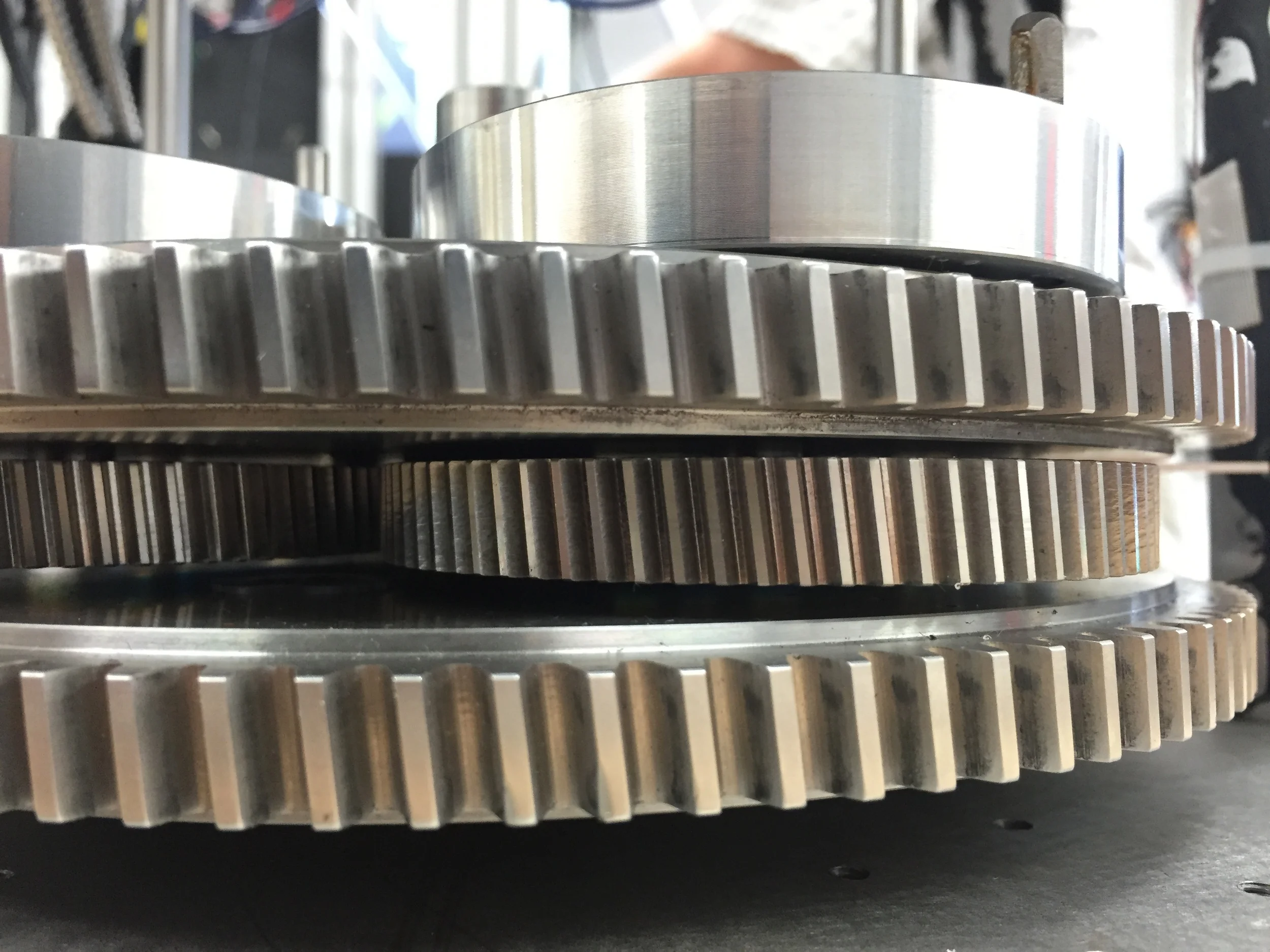

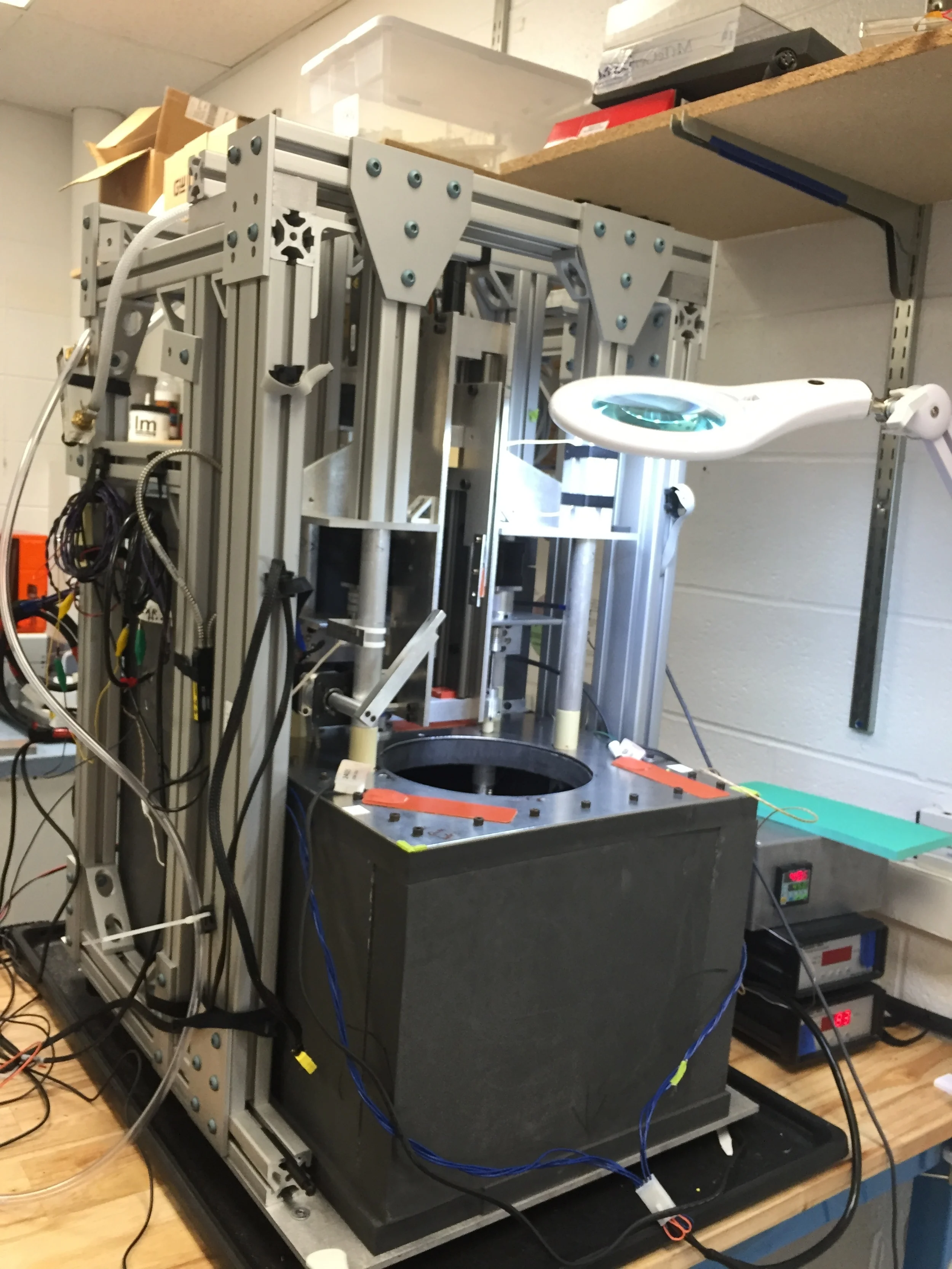

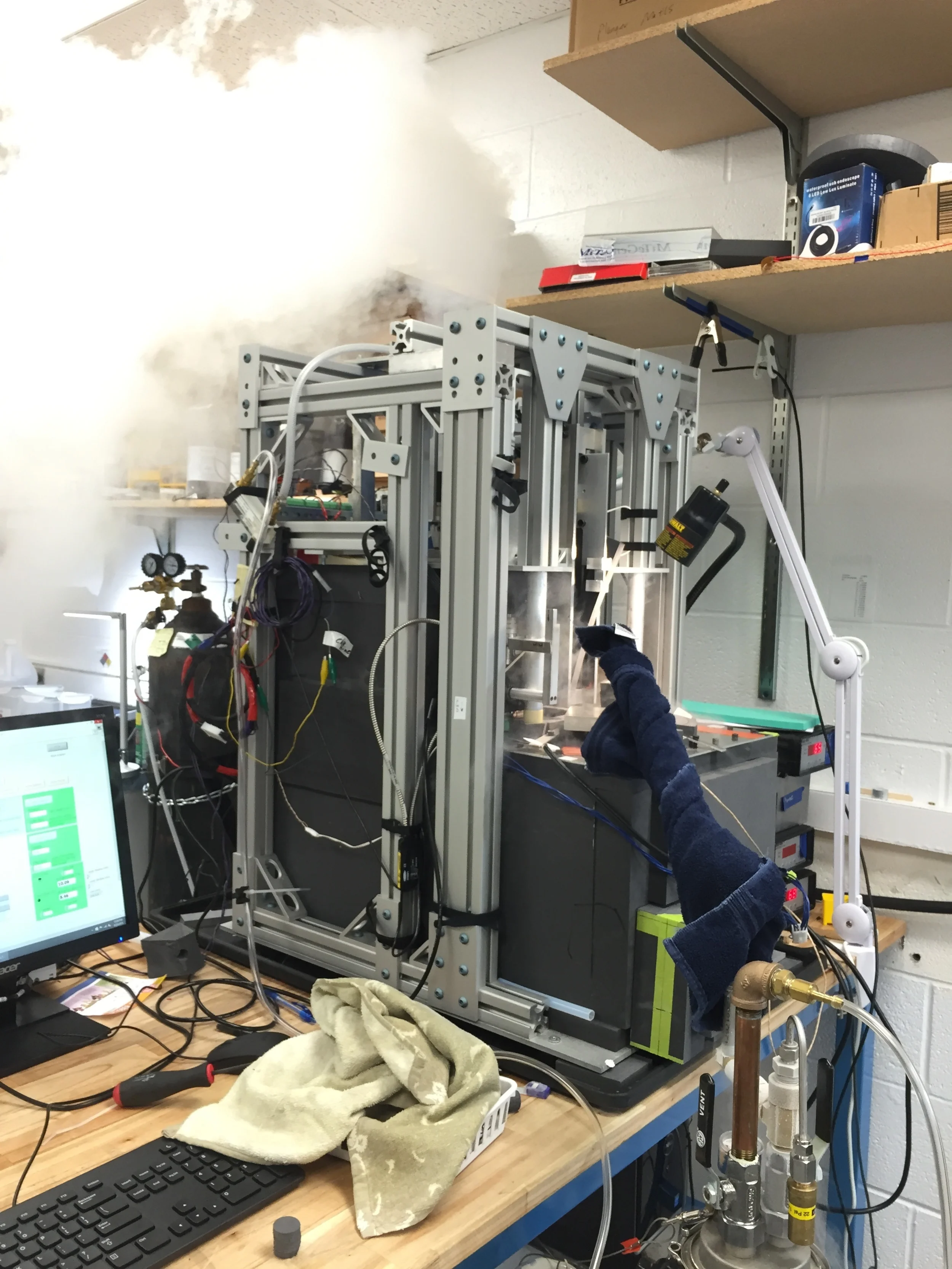

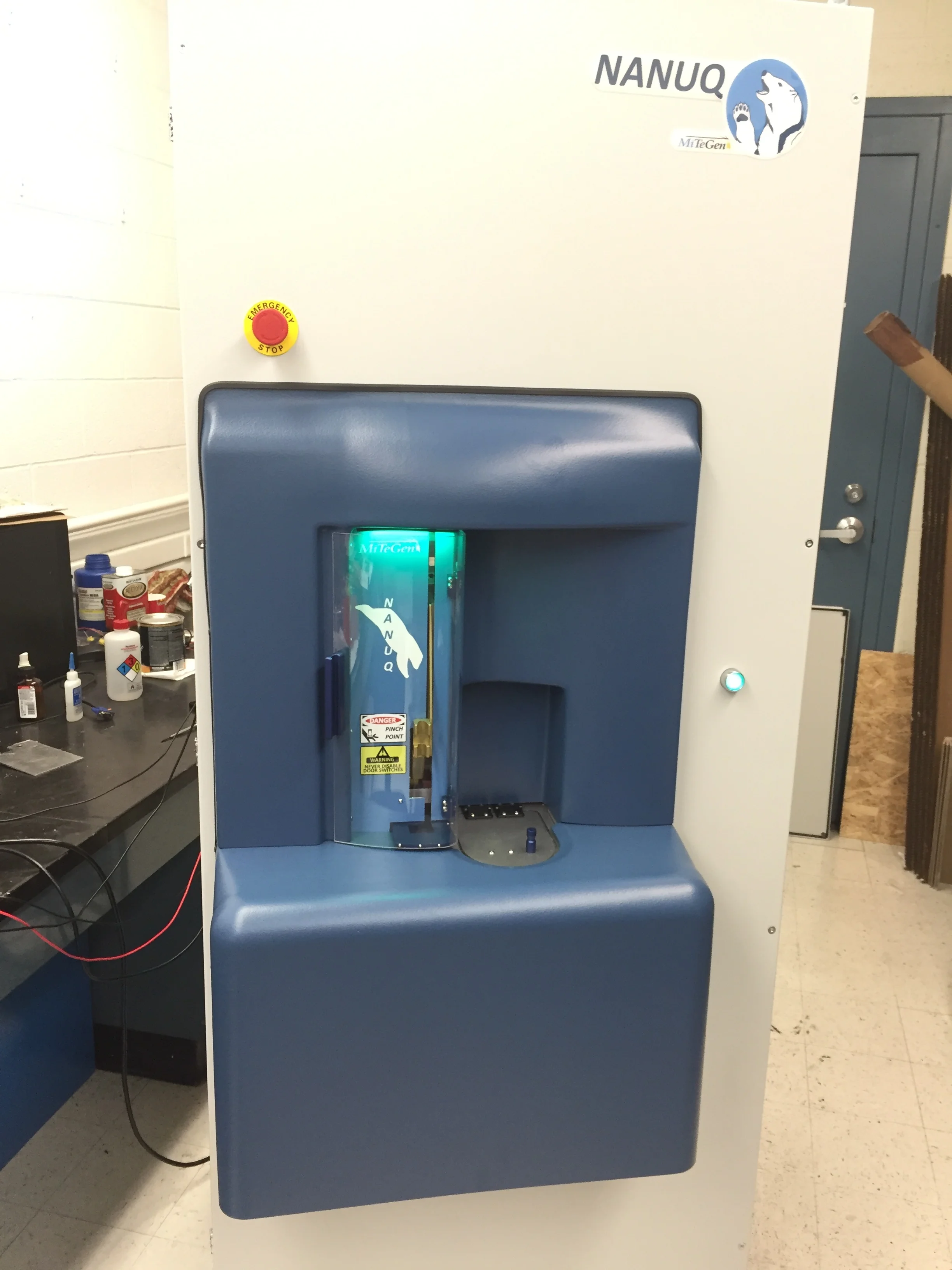

Here are some images of the development work on the Hyperquencher. About half of my time at Mitegen has been geared towards designing this piece of lab equipment. You will see a gear train designed to index and cycle through 64 sample locations of 4 different sample pucks. about 70% of this system was machined out of house. Once we purchased a mill, we started fabricating small components such as housings and motor mounts.

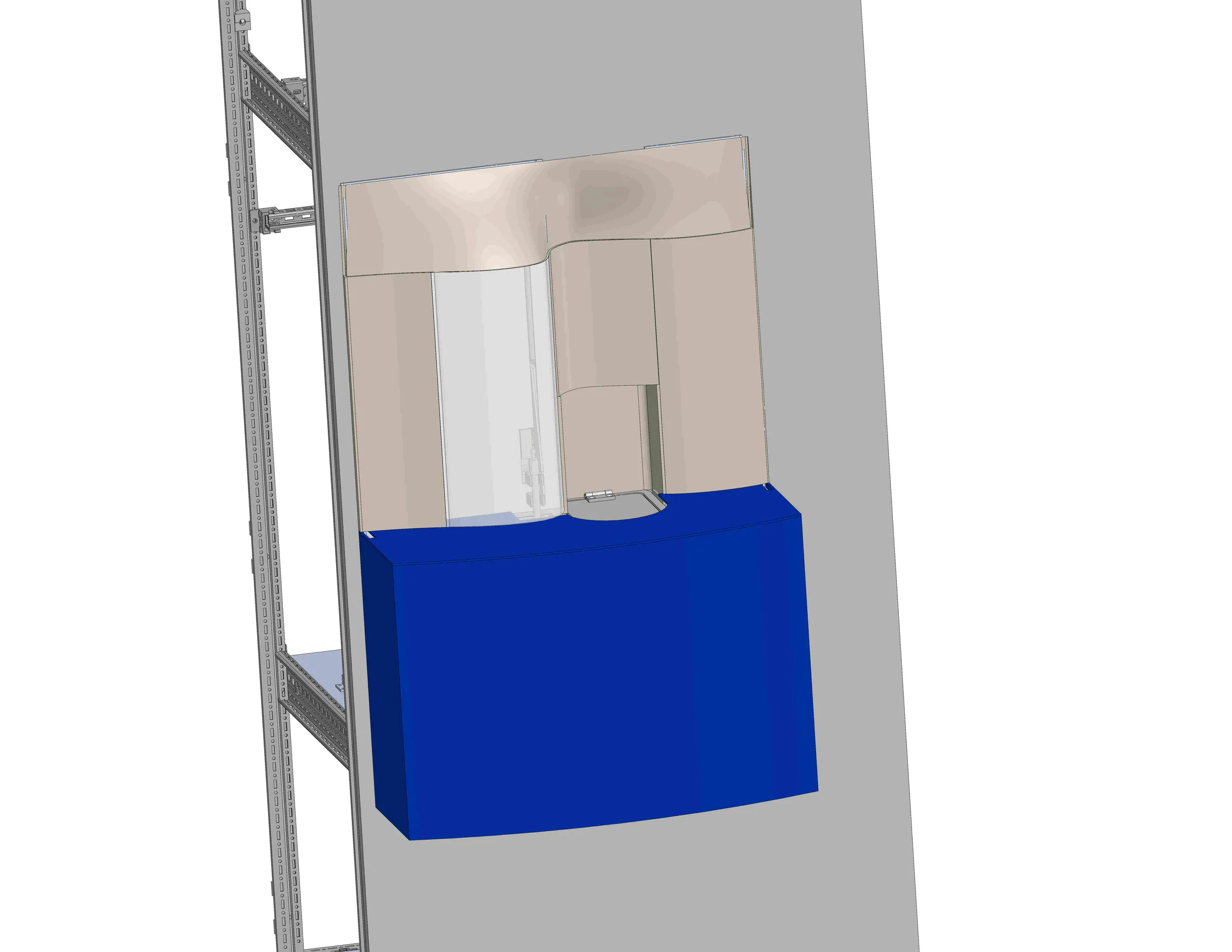

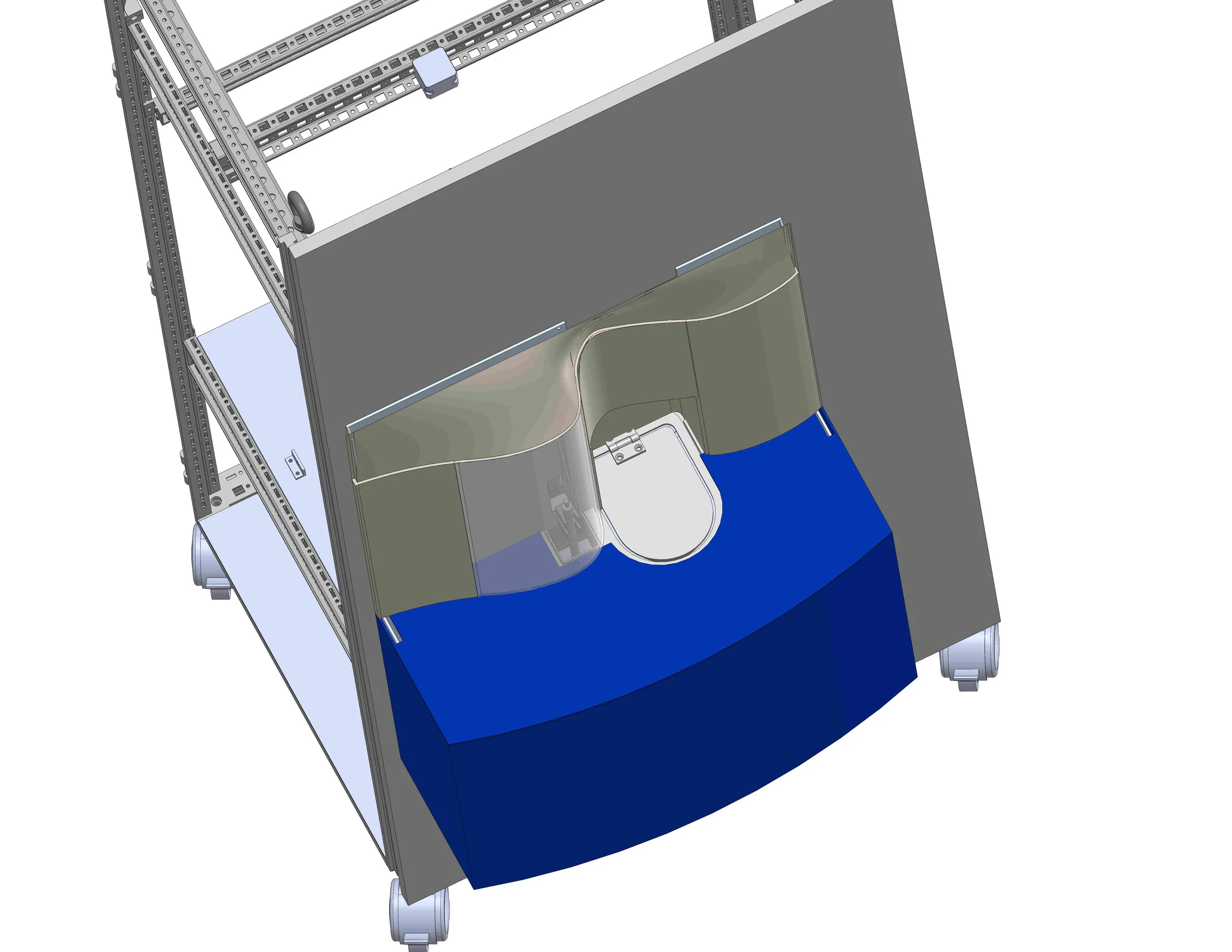

Below are some CAD concepts for future production unit fascia. These individual fascia have been designed with a combination of vacuum forming and thermo-forming in mind.

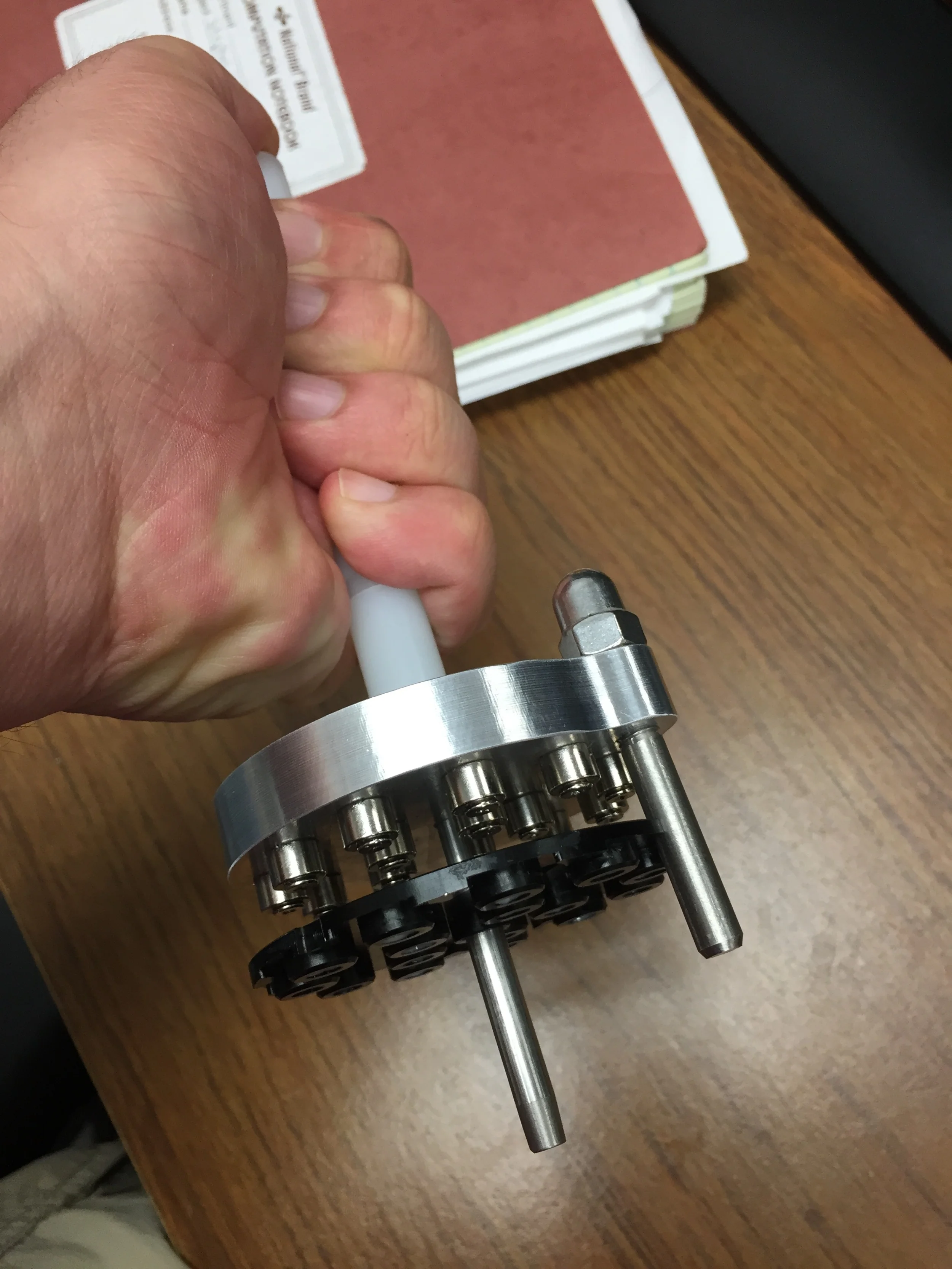

This a tool I designed is called the "Uniwand". These pictures show the first article tool which was machined out of house. Future parts will be machined in house.

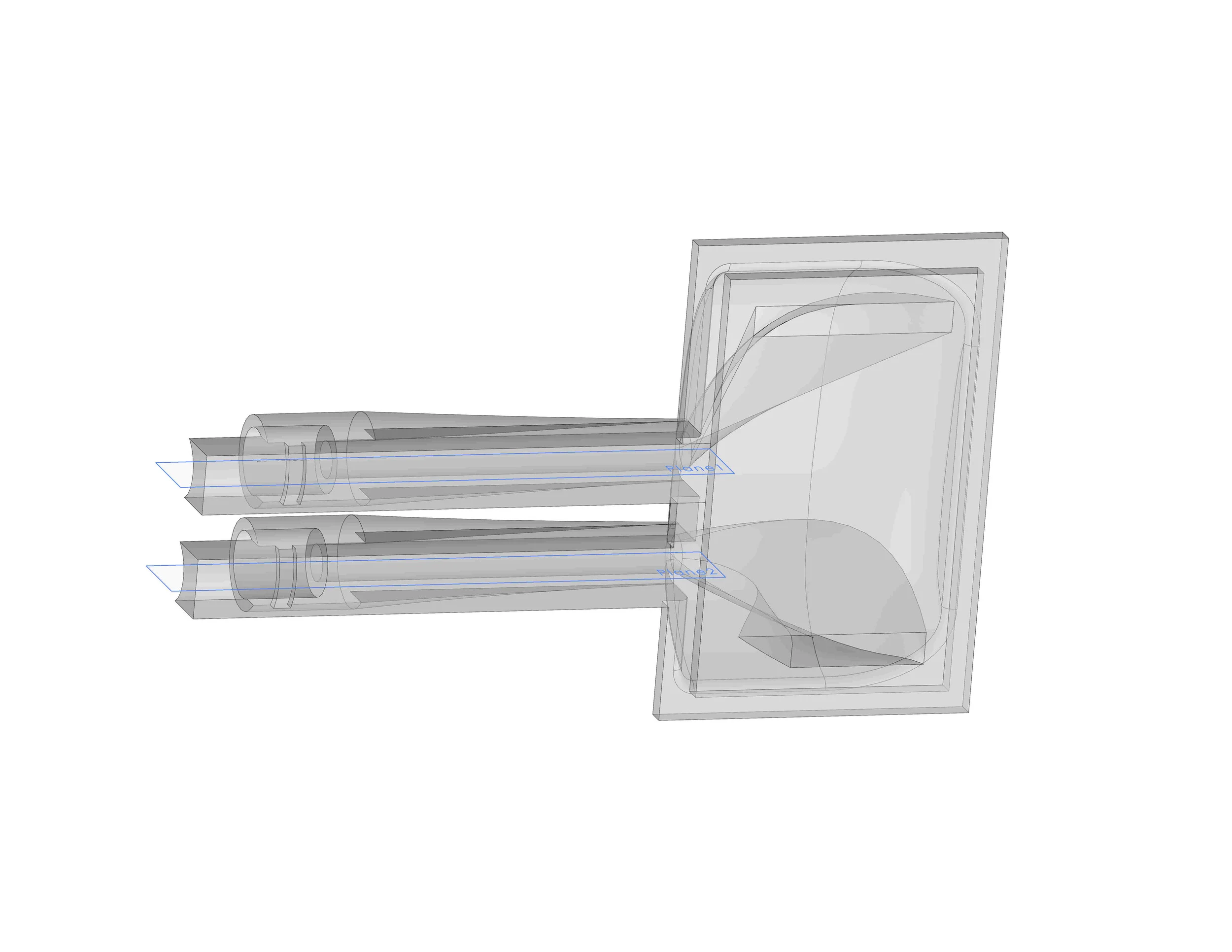

Here are a few images of some recent CAD in SolidWorks.

I fabricated this "wand" for individual sample handling out of stock material.